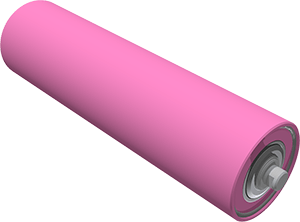

Weigh Conveyor Rollers

do you have a project we can help with?

Weigh Conveyor Rollers

Kimbah Industrial’s weigh rollers are designed to be used on conveyor weightometers where minimal vibration and idler concentricity are critical. They are typically also utilised on the weightometer lead-in and lead-out rollers to ensure belt stability through the weighing zone. Kimbah’s weigh rollers comprise steel bearing housings and a steel shell, which are welded together. This ensures there is no risk of housings separating over time from factors including heavy loading, moisture ingress and thermal expansion. The bearing housing is designed in a way that ensures that, in the event of shell failure, the traditional sharp edge that can “pizza cut” the belt doesn’t exist.

Our weigh rollers are supplied with 2RS NSK greased-for-life bearings and include double-sided triple-labyrinth seals, plus a dust seal which also includes a labyrinth seal. Weigh rollers are suitable for heavy duty applications, in materials handling applications ranging from the smallest quarries up to major mining operations (iron ore, hard rock, black coal, etc,). Weigh rollers are suitable for underground applications. They are powdercoated as standard and can be coloured to your choice.

Features and Benefits

Available in shaft diameters from 20mm to 60mm

Available in shell diameters from 88.9mm to 193.7mm

Total Indicated Runout (TIR) = 0.1mm

Maximum out-of-balance tolerance of 0.014Nm

Maximum Indicated Slope (MIS) < 0.03mm/6o of rotation

Dynamically balanced to ISO 1940.1 G16 or better

Suitable for underground applications

Fitted with a levelling screw on each shaft end to enable fine-tuning adjustment