Ultraroll HDPE Conveyor Rollers

do you have a project we can help with?

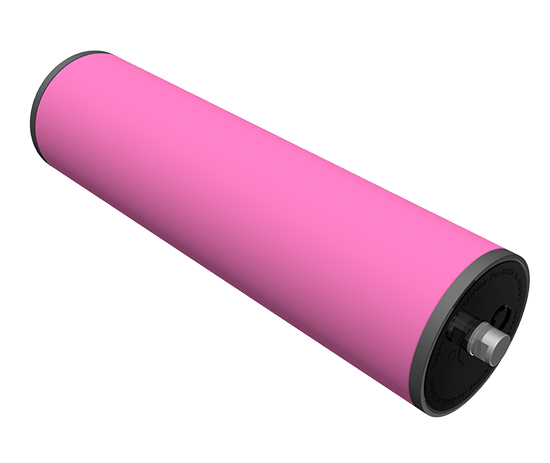

Ultraroll HDPE Conveyor Rollers

Kimbah Industrial’s UltraRoll rollers are our lightweight composite conveyor rollers that provide high performance and durability using cutting edge polymer technology and high-precision manufacturing techniques. UltraRoll Rollers comprise a glass-reinforced HDPE shell with reinforced composite bearing housings that are friction-welded in place. This ensures there is no risk of housings separating over time from factors including heavy loading, moisture ingress and thermal expansion. The combination of the bearing housing material and the geometric design ensures that, in the event of shell failure, there is no hard, sharp edge that can “pizza cut” the belt.

UltraRoll rollers are supplied with 2RS FAG greased-for-life bearings and include non-contact centrifugal seals with a stationary full rock shield, which prevents roller damage from entrapped rocks. UltraRoll rollers are specially designed to dissipate heat during operation. They are up to 60% lighter than conventional steel rollers, with the reduced rotating mass providing tangible reductions in conveyor demand power. UltraRoll rollers also provide an average 4dB reduction in noise emissions in comparison to steel rollers.

If you are looking to increase your conveyor uptime and productivity considerably more, look no further than our Dual-Layer UltraRoll. Our Dual-Layer UltraRoll rollers differentiate from our standard UltraRoll rollers as they feature a 10mm wear indicator. As the lifespan of your Dual-Layered UltraRoll roller comes to an end, the coloured layer will wear out and a new layer will appear. This serves as a visual aid to let you know that this roller needs changing out. With our Dual-Layered UltraRoll roller, you will be able to plan roller changeouts based on actual wear.

UltraRoll rollers are suitable for heavy duty, high speed, corrosive and/or abrasive applications, in materials handling applications ranging from the smallest quarries up to major mining operations (iron ore, hard rock, black coal, etc..)

Features and Benefits

Up to 60% lighter than a conventional steel roller

Available in shaft diameters from 20mm to 60mm

Available in shell diameters from 114.3mm to 219.0mm

Total Indicated Runout (TIR) = 0.2mm maximum

Maximum out-of-balance tolerance of 0.028Nm

Average 4dB quieter than steel rollers

Stationary full rock shield