Steel Hybrid Conveyor Rollers

do you have a project we can help with?

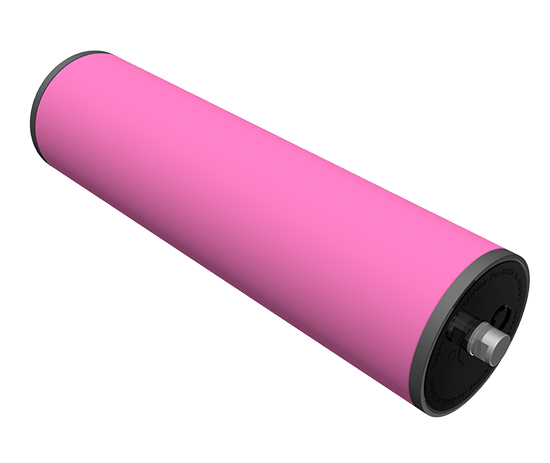

Steel Hybrid Conveyor Rollers

Kimbah Industrial’s steel hybrid rollers combine the benefits of steel rollers and composite rollers. They comprise reinforced composite bearing housings pressed into a steel shell. The combination of the bearing housing material and the geometric design ensures that, in the event of shell failure, there is no hard, sharp edge that can “pizza cut” the belt.

Our steel rollers are supplied with 2RS FAG greased-for-life bearings and include non-contact centrifugal seals with a stationary full rock shield, which prevents roller damage from entrapped rocks. Steel hybrid rollers are suitable for heavy duty applications, such as impact or high-tension areas, where rollers with steel housings are undesirable. They are suitable for heavy duty, high speed, corrosive and/or abrasive applications, in materials handling applications ranging from the smallest quarries up to major mining operations (iron ore, hard rock, black coal, etc,). Steel hybrid rollers have powder-coated shells as standard and can be coloured to your choice. Other coating options, which can improve shell life include:

Inorganic Zinc Silicate Primer

Galvanising

Rubber Lagging

FRAS Rubber Lagging

Ceramic Lagging

Polyurethane Lagging

Features and Benefits

Available in shaft diameters from 20mm to 60mm

Available in shell diameters from 88.9mm to 219.0mm

Total Indicated Runout (TIR) = 0.5mm maximum up to 750mm rollers and 0.00067 x L for >750mm rollers

Maximum out-of-balance tolerance of 0.028Nm

Stationary full rock shield