Industrial Conveyor Frames

do you have a project we can help with?

Industrial Conveyor Frames

Kimbah Industrial is synonymous with precision engineering and dependable solutions in the conveyor manufacturing industry. Our conveyor frames stand out as a testament to our commitment to quality and performance, consistently exceeding expectations across industries. Here’s an in-depth look at how the superior features of Kimbah Industrial frames—structural strength and stability, precise alignment, corrosion and wear resistance, and low maintenance requirements—make them the ideal choice for your conveyor systems.

Structural Strength and Stability

The foundation of any efficient conveyor system lies in its frame, and at Kimbah Industrial, we prioritise unmatched structural integrity. Our conveyor frames are constructed using high-strength materials such as structural-grade steel or aluminium, ensuring they can withstand the heaviest loads and the most demanding industrial environments. Whether supporting bulk materials in a mining operation or high-speed packages in a warehouse, our frames remain steadfast under pressure.

Our engineers meticulously design every frame to minimise flexing, vibrations, and deformation. This attention to detail ensures not only the longevity of the frame itself but also the protection of other conveyor components, such as rollers and belts. Even under dynamic loads or extended use, Kimbah Industrial frames maintain their stability, ensuring smooth and reliable operations. By investing in structurally robust frames, businesses benefit from reduced downtime, improved efficiency, and peace of mind.

Precise Alignment for Optimal Performance

Kimbah Industrial frames are renowned for their precision. Proper alignment of conveyor components is critical to ensuring seamless material handling. Misaligned rollers or belts can cause a host of issues, from increased friction and wear to reduced performance and energy inefficiency. Our frames are designed and manufactured with meticulous accuracy, guaranteeing the perfect alignment of all components.

To maintain this precision over time, our frames feature adjustable mechanisms, allowing easy realignment as needed. This adaptability ensures that conveyor systems continue to perform at their peak, even after years of heavy use. Furthermore, the precise alignment reduces the likelihood of uneven wear or unnecessary strain on components, contributing to longer equipment lifespans and overall cost savings.

Corrosion and Wear Resistance for Longevity

Industrial environments can be harsh, exposing conveyor frames to moisture, chemicals, abrasion, and extreme temperatures. Kimbah Industrial frames are engineered to withstand these challenges with advanced corrosion and wear resistance features. Whether operating in a wet food-processing facility or a dusty mining site, our frames perform reliably without succumbing to environmental factors.

We utilise premium-grade materials and protective finishes, such as powder coating, galvanisation, painted or stainless-steel construction, to prevent rust and degradation. These protective measures extend the life of our frames, ensuring consistent performance and minimising the need for repairs or replacements. By choosing Kimbah Industrial, businesses can count on durable, weather-resistant frames that stand the test of time in even the toughest conditions.

Low Maintenance Requirements

At Kimbah Industrial, we understand that downtime and frequent maintenance can disrupt operations and drive-up costs. That’s why our conveyor frames are designed for simplicity and reliability, requiring minimal upkeep. High-quality materials and finishes reduce wear and tear, while precise engineering minimises component stress, ensuring that maintenance intervals are few and far between.

Additionally, our frames feature accessible designs that make inspections and repairs quick and straightforward. Smooth surfaces reduce the buildup of dirt or debris, further simplifying cleaning and maintenance tasks. With Kimbah Industrial frames, businesses can focus on their operations rather than worrying about frequent breakdowns or complex servicing needs.

Kimbah Industrial conveyor frames are the epitome of excellence, combining structural strength, precise alignment, corrosion resistance, and low maintenance requirements. These features not only enhance the efficiency and reliability of conveyor systems but also provide long-term value and peace of mind for businesses. When you choose Kimbah Industrial, you’re investing in a product that is engineered to perform, designed to last, and supported by a commitment to your success. Trust in Kimbah Industrial frames to elevate your material handling operations to new heights!

Our Frames

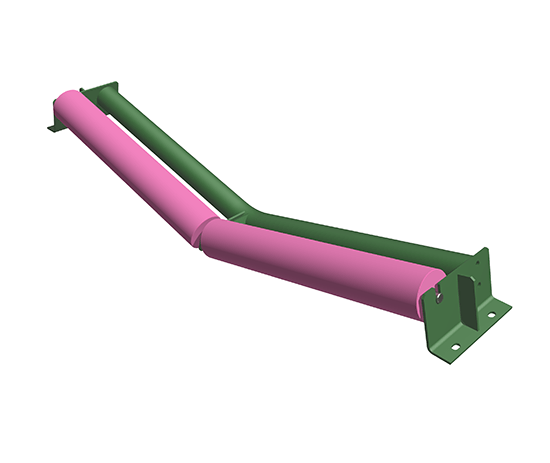

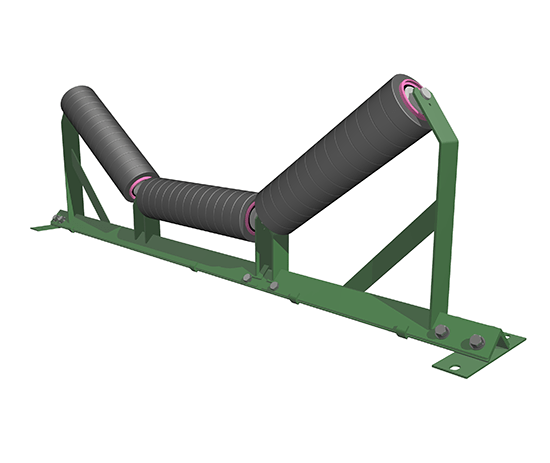

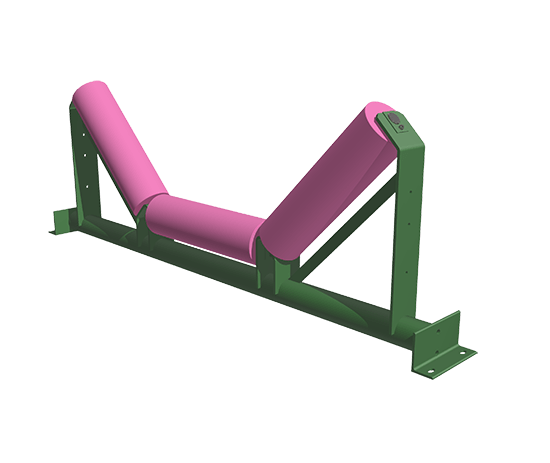

Vee Return Frames

Kimbah Industrial's vee return idler frames are high-quality products exceeding industry standards. They assist with belt tracking, offer various configurations, and support standard or customized rollers. Available in multiple finishes and belt widths, they ensure durability and precision.

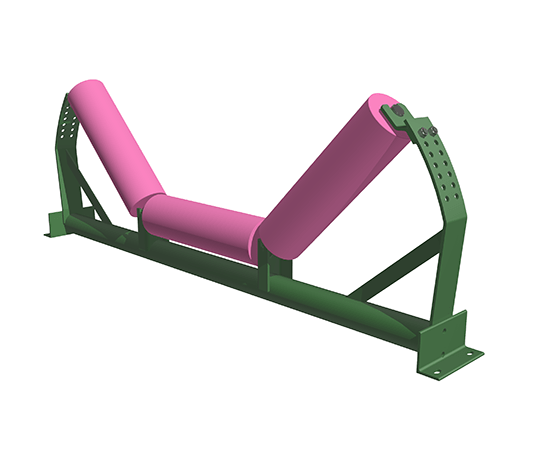

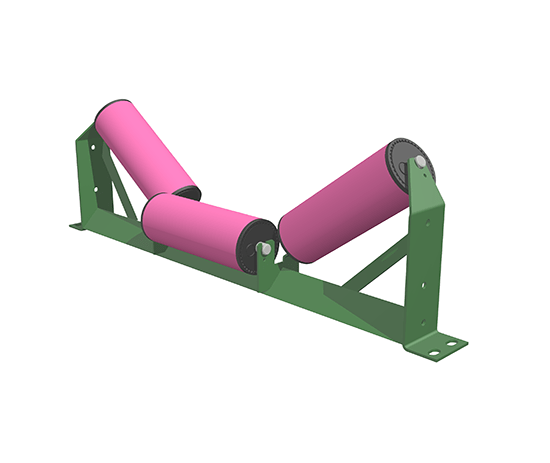

Transition Frames

Kimbah Industrial’s transition idler frames are designed for belt transition zones, exceeding industry standards through advanced manufacturing techniques. Available in 3 or 5-roll configurations, they suit various belt widths, finishes, and adjustment ranges.

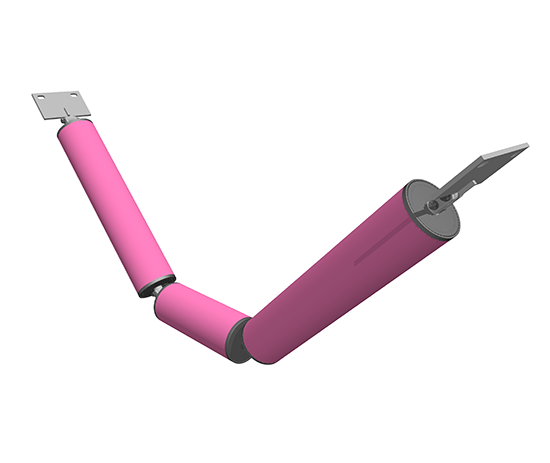

Suspended Carry Frames

Kimbah Industrial's suspended carry idlers excel in quality and durability, handling loads from chute to discharge in adjustable conveyor alignments. With customizable connections, configurations, and finishes, they suit various belt widths and roller setups efficiently.

Rigid Suspended Carry Frames

Kimbah Industrial’s rigid suspended carry idler frames are built for high-tension applications like tripper transition zones. Customizable in configurations and finishes, they suit various belt widths and ensure precise roller positioning with exceptional durability.

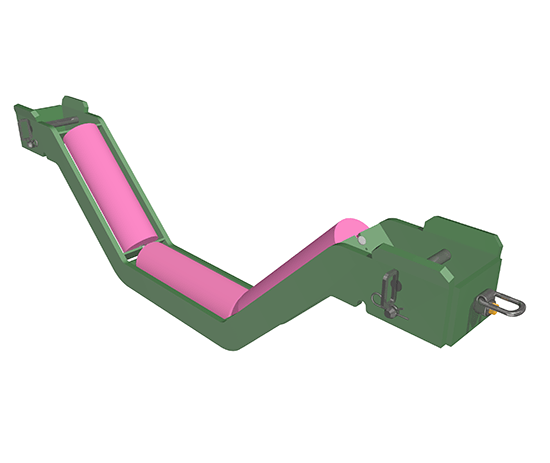

Retractable Impact Frames

Kimbah Industrial’s retractable impact idler frames excel in impact zones, enabling efficient roller maintenance with retractable elements. Customizable in configurations, finishes, and belt widths, they support both impact and standard rollers for diverse applications.

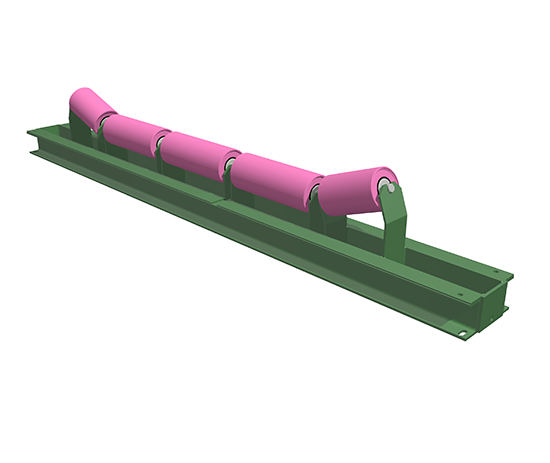

Picking Carry Frames

Kimbah Industrial's picking carry idler frames are ideal for applications needing less troughed belt profiles, like feeders or recycling conveyors. Customizable in configuration, finishes, and roller types, they suit various belt widths with precision and durability.

Offset Carry Frames

Kimbah Industrial’s offset carry idler frames, designed for thinner belts, ensure durability and tracking with forward-tilted wing rollers and overlap to prevent belt damage. Available in various configurations, finishes, and sizes, they cater to diverse belt needs.

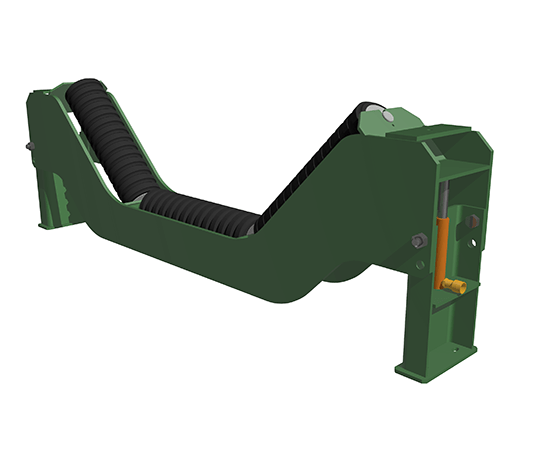

Jackdown Impact Frames

Kimbah Industrial’s jackdown impact idler frames are ideal for impact zones, enabling efficient roller maintenance with hydraulic lowering. Customizable in configurations, finishes, and roller setups, they suit various belt widths and ensure reliable performance.

Inline Carry Frames

Kimbah Industrial’s inline carry idler frames deliver unmatched quality for load-bearing applications. Available in diverse configurations, finishes, and roller setups, they suit various belt widths, ensuring reliability and performance from chute to discharge.

Flat Return Tracker

Kimbah Industrial’s flat return trackers ensure precise belt tracking without servo rollers, avoiding belt edge damage. Featuring a compact, maintenance-free design, they suit single or reversing belts and are customizable for various belt widths and applications.

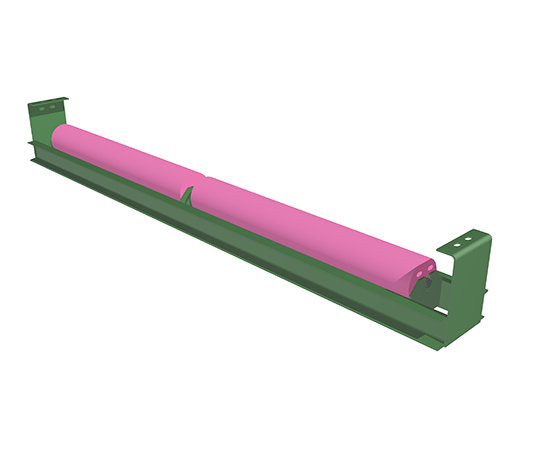

Flat Return Frames

Flat Return Frames

Kimbah Industrial’s flat return trackers are engineered and fabricated to exceed industry standards and/or customer specifications. Manufacturing techniques include CNC laser cutters and robotic welding. The combination of high-tech manufacturing equipment, AS1554.1 SP welding and our high-quality management/assurance systems ensures all flat return trackers

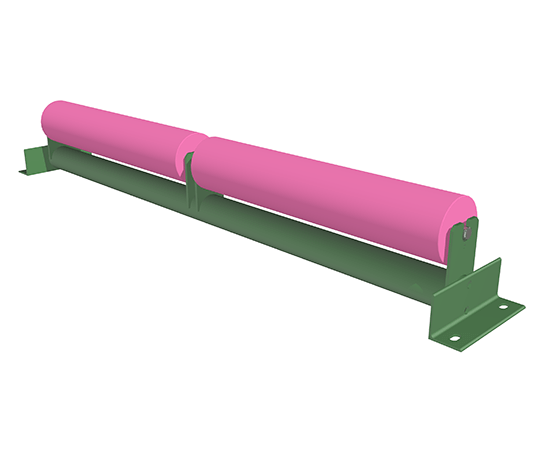

Flat Carry Frames

Kimbah Industrial’s flat carry idler frames ensure top-tier quality for flat belt applications like take-up zones. Available in 1, 2, or 3-roll configurations, they are customizable in sizes, finishes, and roller setups to suit diverse conveyor needs with precision.

Carry Tracking Frames

Kimbah Industrial’s carry trackers provide precise belt tracking without servo rollers, reducing edge damage. Featuring conical wing rollers for accurate alignment, they are compact, maintenance-free, and customizable for various belt widths and configurations.

What Makes Us Different

Our Commitment to Sustainability

As a responsible business, Kimbah Industrial is committed to sustainability. We are continually seeking ways to reduce our environmental impact, from the materials we use to the processes we employ. Our Legodock pontoon systems, for example, are made from 100% recyclable materials, reflecting our dedication to eco-friendly solutions that benefit both our clients and the planet.

Our Team

Behind every successful project is a team of dedicated professionals. At Kimbah Industrial, our team brings together a wealth of experience and a shared commitment to excellence. From engineers and technicians to customer service representatives, every member of our team plays a vital role in delivering the high standards of service and quality that our clients expect.

Looking Ahead

As we look to the future, Kimbah Industrial remains committed to growth and innovation. We will continue to explore new technologies, expand our product offerings, and enhance our services to better meet the needs of our clients. Our goal is to remain at the forefront of the materials handling industry, providing solutions that drive success for our clients, now and in the years to come.